QCCodeConfiguration

QC Code Configuration

The fundamentals of Quality Control are built around QC codes.

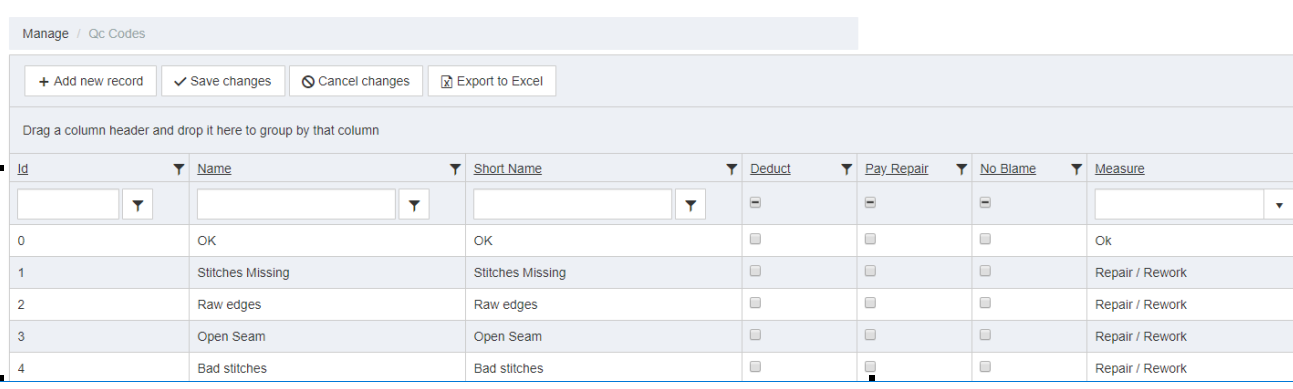

These can be managed through Manage-QC Codes.

In this view there are several options that can be assigned to a QC code when setting up depending on the desired results.

To begin with QC Codes need to be created and assigned Id, Name, and Short Name, the short name will be shown on the tablets.

Parameter flags:

The main part of the QC Codes are how they are set up to handle the transaction data. This controlled by flags and measures.

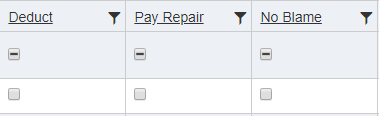

There are three different flags, not selecting any flag will also have an effect.

- Deduct - default setting

When deduct is checked, any audited product that fails QC will trigger a deduction from the user that performed the operation.

This means the earned SMV, Pay, and QTY produced will be deduced from the responsible user. In other words the user will be blamed.

- Not checking Deduct will remove the QTY from the user, but they will keep their earned SMV and Pay.

- Pay Repair - default setting

Pay repair is the opposite of deduct, when a repair is made, having this flag checked will reward the user with SMV, Pay and QTY for the repair operation.

This is logically used together with Deduct to avoid skewed production statistics, more on this later.

- Not checking Pay Repair will result in the user not being rewarded for the repair, they will only receive QTY and Cycle time for the repair.

- No Blame

No blame will, when checked, not blame the user and instead remove the QTY from the Unit/Workorder, but the user keeps their QTY produced and SMV.

This is used in examples where there is no way to blame the user, for example if the fabric is discolored or torn.

- Not checking No Blame will blame the user, however it is used with the other options it will result in the User being deducted of the QTY.

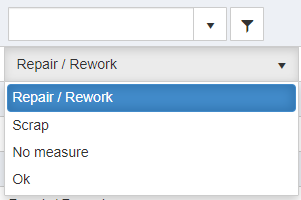

Measures:

Measures are used to define what happens to a piece when audited.

There are four different options here.

- Repair

This measure means that the piece audited will be added to the repair list and would be selected only for a type of issue that is repairable.

Combined with the parameter flags this configures how a QC Code is handled on repair.

- Rework

This measure means that the selected operations will need to be reworked - this will prevent further progress on the Unit of these pieces until the operations are reworked.

By using Rework material consumption can be handled and material will be consumed for the operations that have men marked for Rework.

- Remake

Using the Remake measure will trigger an API call to be made that includes the total qty needing to be remade along with a scrap API call being made to the relevant ERP system

- Scrap

This measure means the item will not be available to repair. This would be used for irreparable items and means that when used the QTY is scrapped and removed from production.

A scrapped item is not possible to return into production.

Combined with the parameter flags this configures how a QC Code is handled when an item is scrapped.

- No Measure

This measure simply means that when an audit is made there is no record or transaction created of the audit.

No Measure should only be used during QC where there is no actual measure. For example an audit was made and there was no issues but also no need to record the audit.

- OK

This measure is used in combination with the Repair / Rework and Scrap measure to identify that an audited piece was not faulty.

OK allows tracking of the quantity of pieces audited to properly record Quality statistics.

For example, if 10 pieces are audited and one was faulty, the 9 pieces without issues would be recorded with an OK measure QC code.

Copyright © 2020 by Aptean. All rights reserved.

Created with the Personal Edition of HelpNDoc: Make the switch to CHM with HelpNDoc's hassle-free WinHelp HLP to CHM conversion tool