SubRoutes

Sub Routes

Sub Routes

Manage > Products > Sub Routes

Definition and Functionality

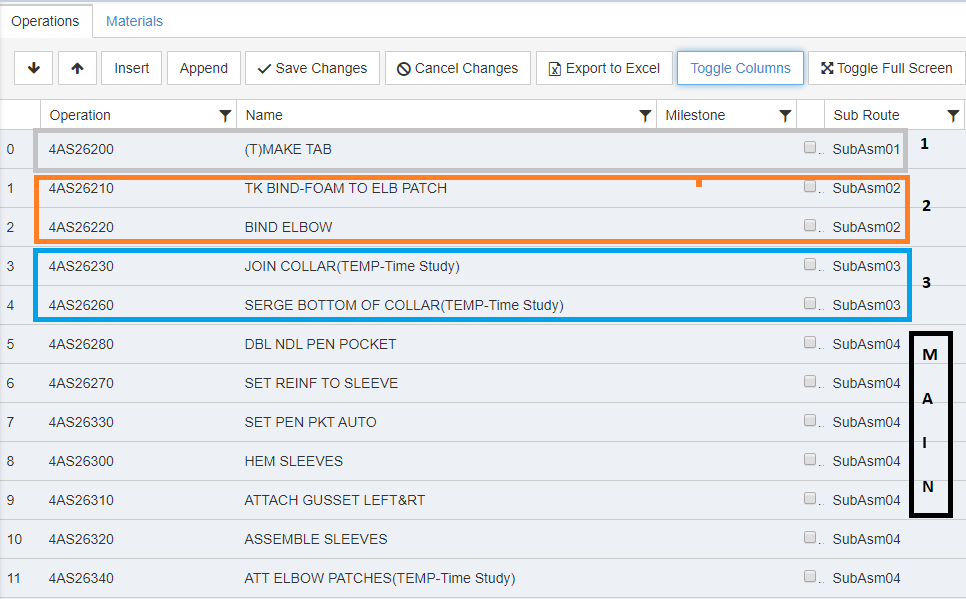

Sub Routes are used when production is split into different sub-assemblies to be done at the same time. Sub Routes are assigned to a group operations or sequences to manufacture the sub-assembly.

Sub Routes Menu

Sub routes are used when a component of a product is going to be handled by a part of the production environment that requires it to be separated from the rest of the product. For instance, if a shirt is produced and the collars were being worked on in a different building, the operation can be marked as a sub-route on this page

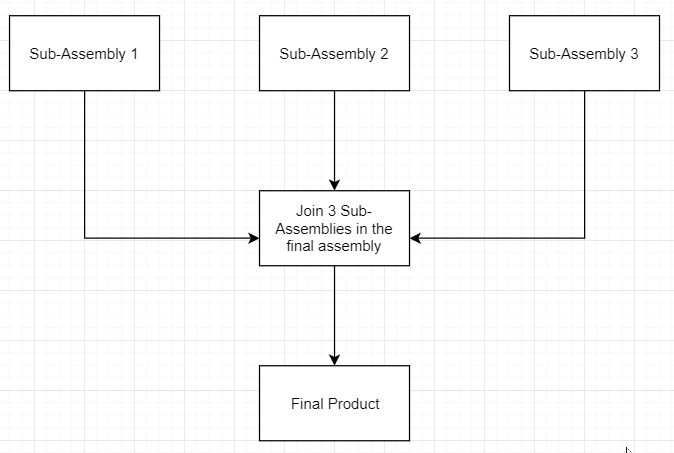

Sub Routes are an important part when building the product. Depending on the complexity of the product, it could have one or more subsets. Sub Routes are a link to the print label of the work order. This function determines where the subset is made and can only allow scanning within the sequence of operation for that subset, i.e. below shows a product with 3 sub-assemblies made before the main or final assembly.

The result of this is that sub route labels can be printed for scanning by the Shopfloor terminals, that contain information linking it to the rest of the product components so they can be reliably brought back together.

This is an outline of how the sub routes work and are created in Shopfloor

- The operation that will be performed as a subroute, so in another facility or section your facility must be established

- The operation(s), in this example the 'collar' operation for our shirt will be done as a sub route

- The sub route must be defined under the MANAGE - PRODUCTS - SUB ROUTES menu. To do this:

- click 'add new record

- give the sub route an ID and a name

- click 'save changes'

- Return to the operations list (bill of operations) for the product you're creating

- Create or modify the list with all the operations that must be performed on this product by clicking 'insert', 'append', or the arrow buttons

- On the line containing the operations that will be performed as a subroute, choose the correct subroute from the drop-down menu. In the example below, operation 101 is the subroute operation

- If no other changes need to be made to this list, click the 'save' button

- Now that the operation list has been created, the unit labels can be created. You will notice that a regular unit label is created, as well as a copy of that label with the word 'SUB' printed on it. This second label should be associated with the units/bundles of product that will be worked on on the subroute, meaning the other plant or other part of your production facility

Copyright © 2020 by Aptean. All rights reserved.

Created with the Personal Edition of HelpNDoc: Create Professional CHM Help Files with HelpNDoc's Easy-to-Use Tool