Products

Products

Definition and Functionality

A product is a Style, and is defined by its BOL (sequence of operations with their SAM) and Materials. Each Product has an ID and a Name so that users, supervisors and other integrated systems can relate to the product. The product ID can be alpha numeric and also supports the following special characters Hyphen-, Underscore_ and Pound #

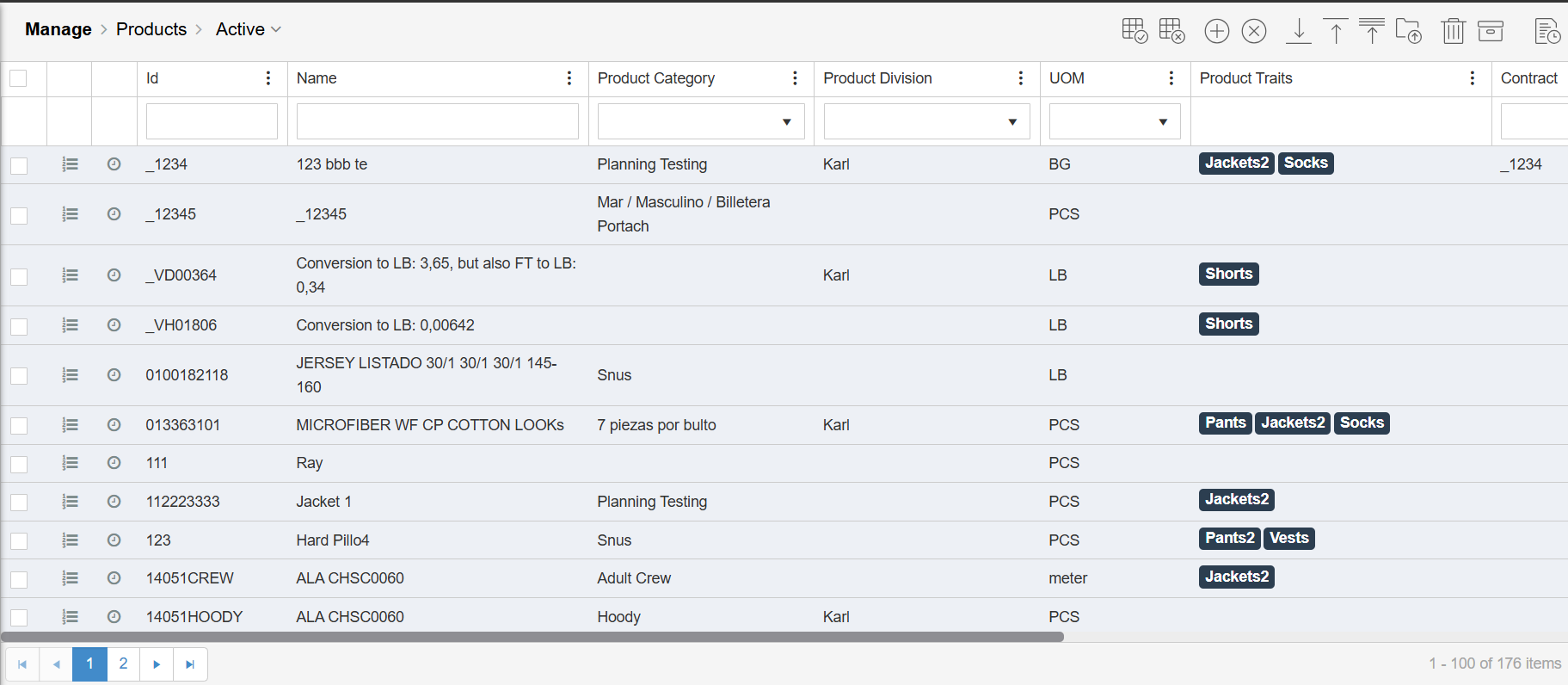

Product Menu

Manage > Products

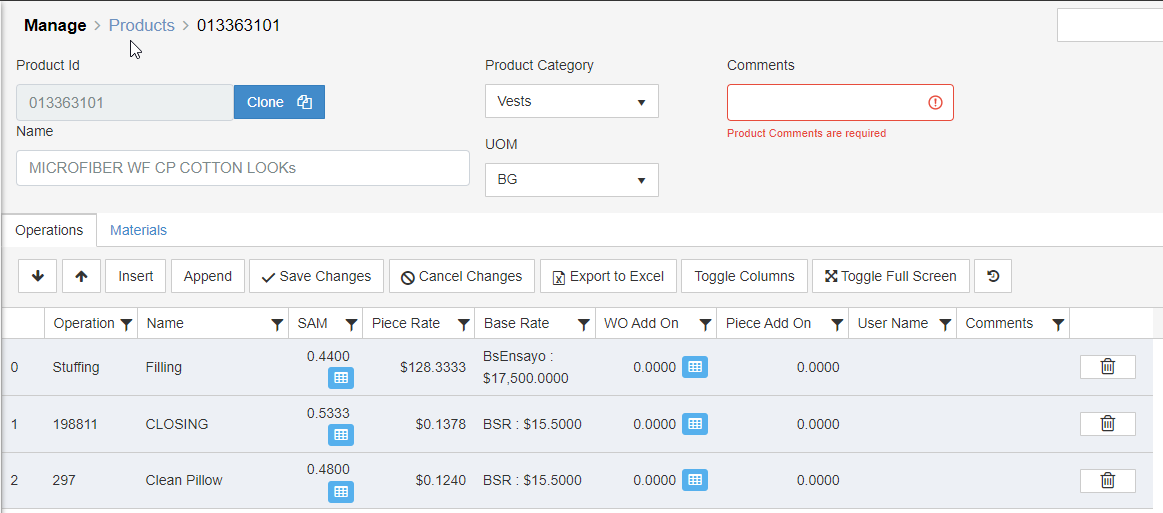

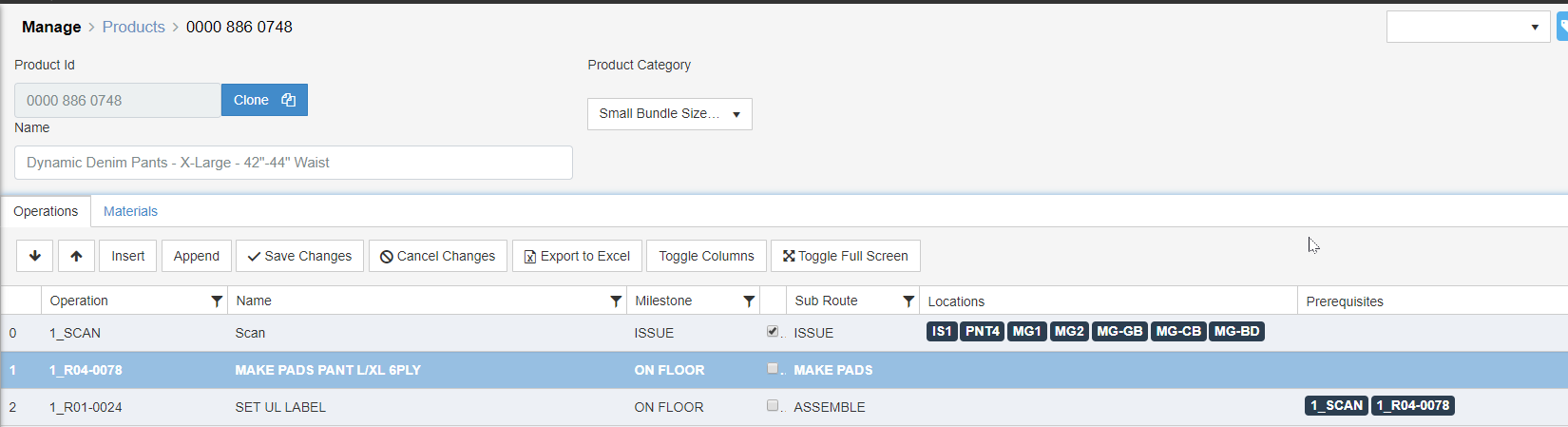

Details Screen – BOL (Bill of Labor)

BOL (sequence of operations) and Materials. The product details screen is where all product components are kept from operations to materials. Operations can have unique characteristics that determine where the operation is reported, the locations where it can be performed, and any kind of prerequisites necessary to continue the sequence.

Engineering

The sequence of operation is maintained with its SAM value, piece rate, base rate and other additional SAM values to be part of the total SAM, that is, additional handling, handling of small packages, etc.

Entire product BOLs can be exported from the main Products menu by hitting the export button at the top right of the screen with one file being generated per product.

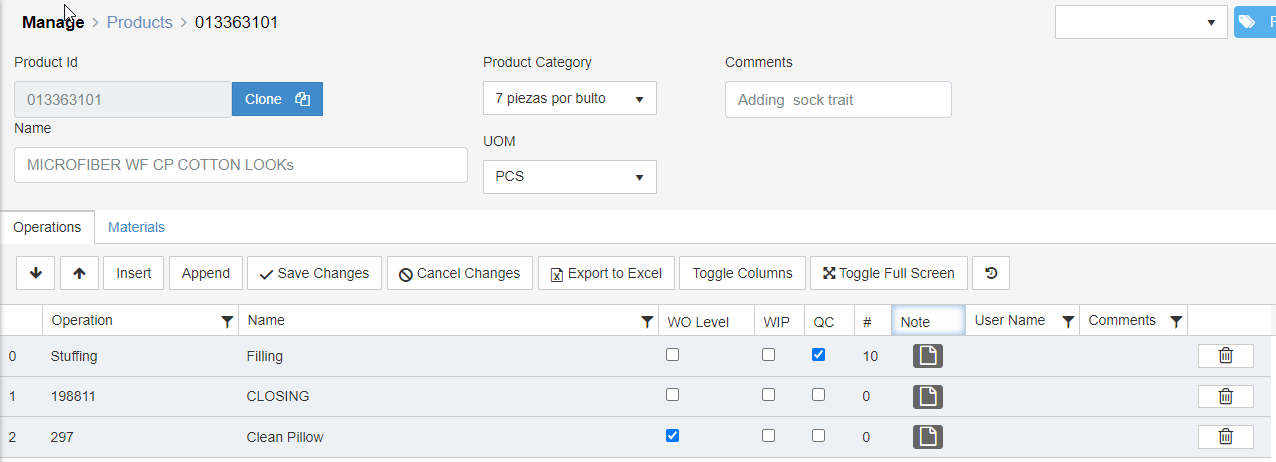

Report Work

There are fields reporting production at the WO (work order level), production, quality, and milestone.

- WO – When production is reported at the WO level, the total order quantity will be credited to the user.

- Production – Reports production per unit (bundle) for the operation performed.

- Quality – The user can report quality defects of previously performed operations.

- Milestone – Production reports by stage, i.e. pre-assembly, cutting, lining, etc.

- Sub Route – It allows to report the production at the same time in different locations..

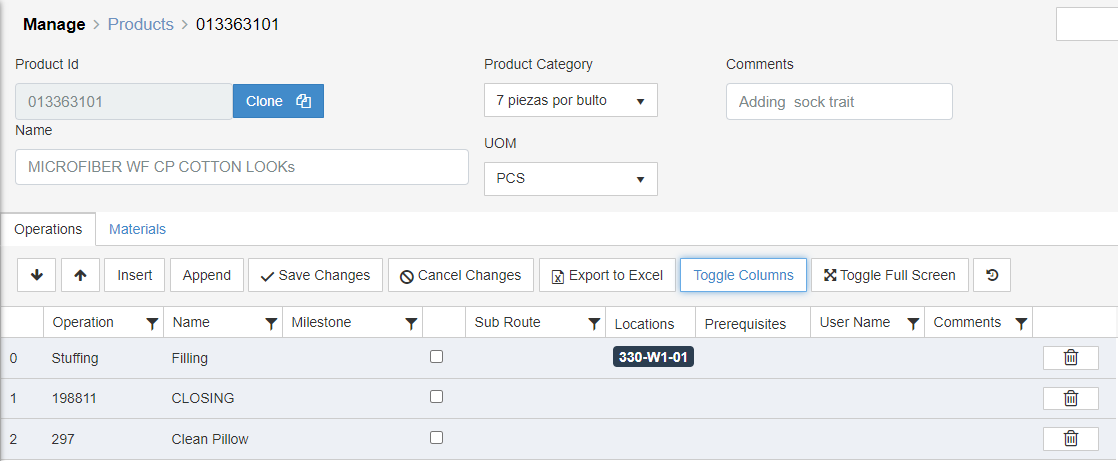

Special Characteristics

These attributes are limited to where they can perform the operation by location and whether the operations prerequisites needed to advance during production.

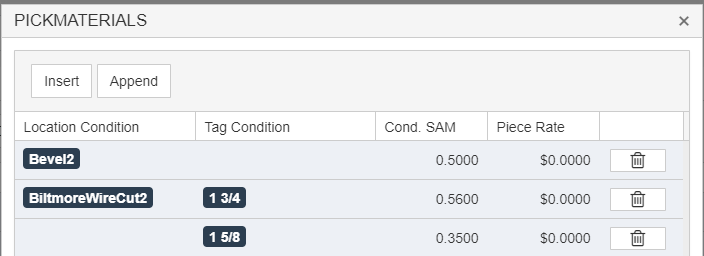

Additional SAM’s engineering options

There are additional engineering options to apply to the operation, i.e. aggregates to the SAM value, conditional SAMs, etc.

Aggregate SAM’s and Conditional SAM’s

They are controlled by tags and location, conditional SAMs replace the SAM value with a tag or location, and aggregate SAMs add additional SAMs to the standard by tag or location and a combination of both.

The engineering reason behind this feature is to increase product versatility without adding more products with the same characteristics. The product can pay different rates by changing locations or tags by size or types of fabrics as an example.

Additional SAM’s by operation

They are configured from the operation menu and activated wherever the operation is used on different products.

Operation Sequence options

Through global parameters, the tablet is enable to report work through different sequence options. These options also will consider the prerequisites and op seq. and zone.

- Complete the current job only if location is assigned to the operation

- Move to the next operation after completing current operation.

- Find the first uncompleted operation.

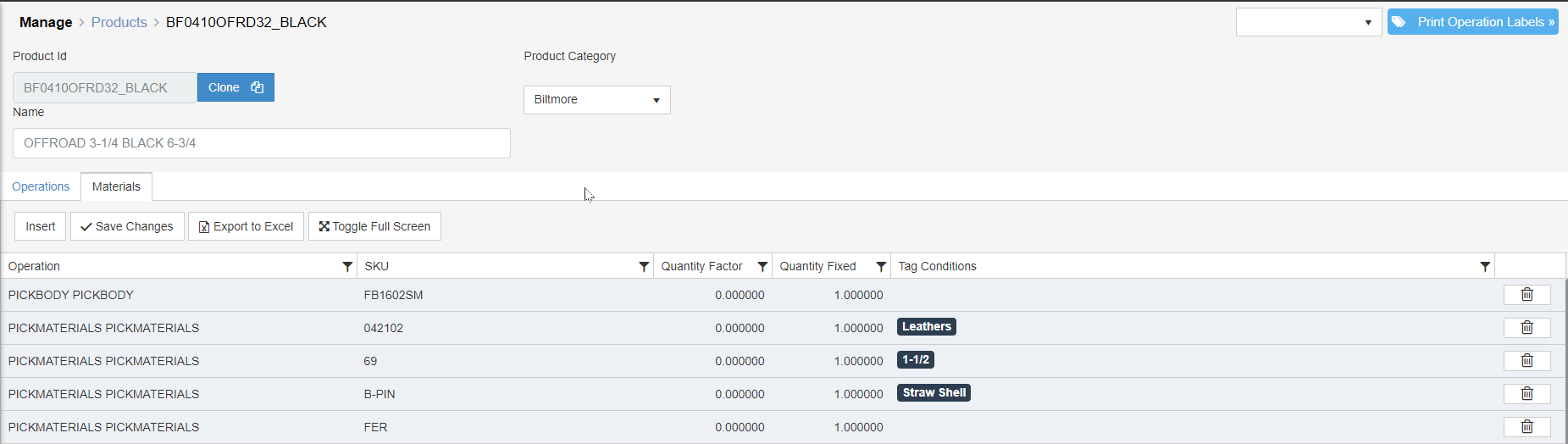

Materials

It is where the BOM is attached to the product and which operation will show the requirements. SFC uses it more as a kiting option. This function allows the user to take the correct amount of materials or accessories to start production.

Copyright © 2020 by Aptean. All rights reserved.

Created with the Personal Edition of HelpNDoc: Experience the Power and Ease of Use of a Help Authoring Tool