ProgressiveManufacturing

Progressive Manufacturing

This type manufacturing tracks the individual processes by operation and creates efficiency based on units made compared to the operation SMV's

To set up progressive manufacturing:

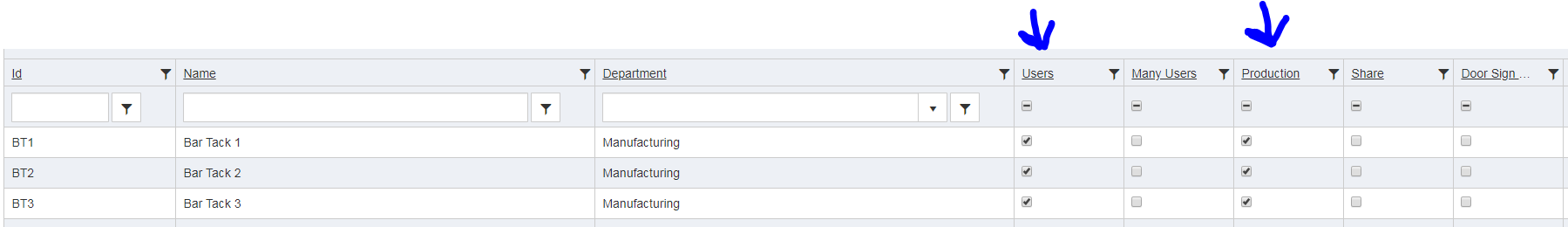

Set up Locations accordingly.

This is done in Manage - Locations.

For progressive manufacturing select single user and production

Location setup:

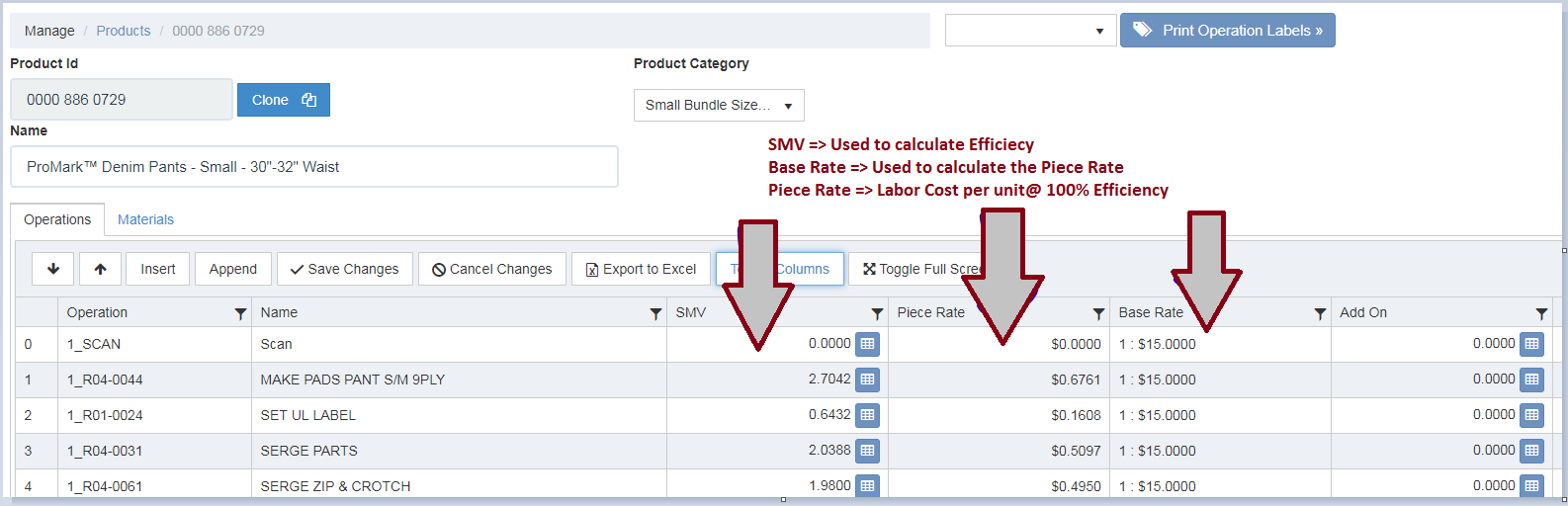

Product Bill of Labor needs to be set up accordingly

Standard SFC operations with SMVs has to be configured to track efficiency.

For Incentive Pay, Base Rate needs to be configured as well in order for Piece Rate to be calculated

BOL setup:

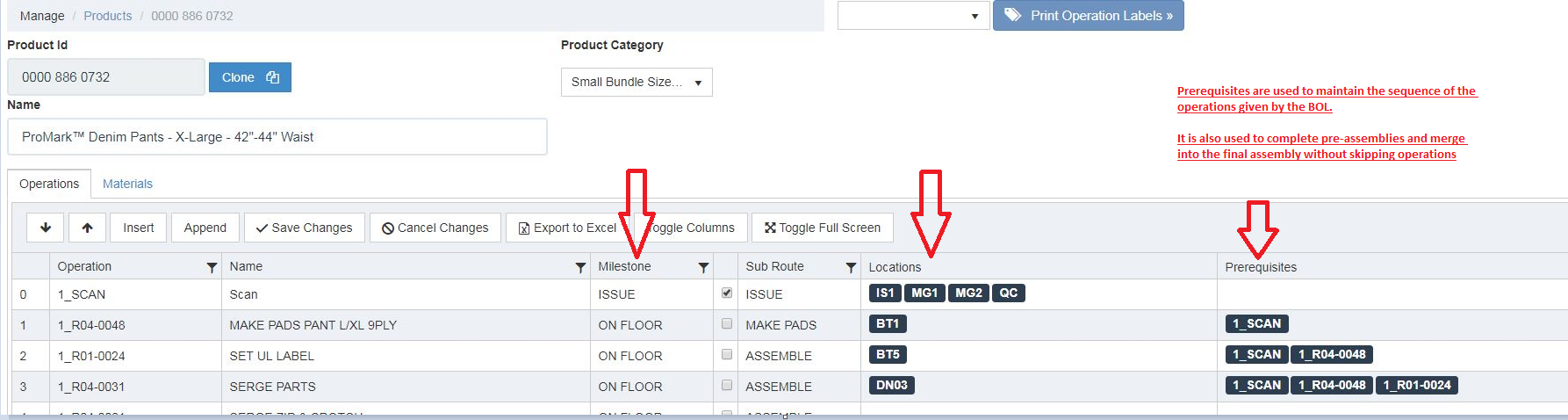

For WIP tracking to function, Milestones need to be set up.

Operations can be locked on to specific locations depending on how the manufacturing line is set up.

In order to maintain the correct BOL sequence, prerequisites can be configured - a certain operation can not be started until prerequisite operation is finished.

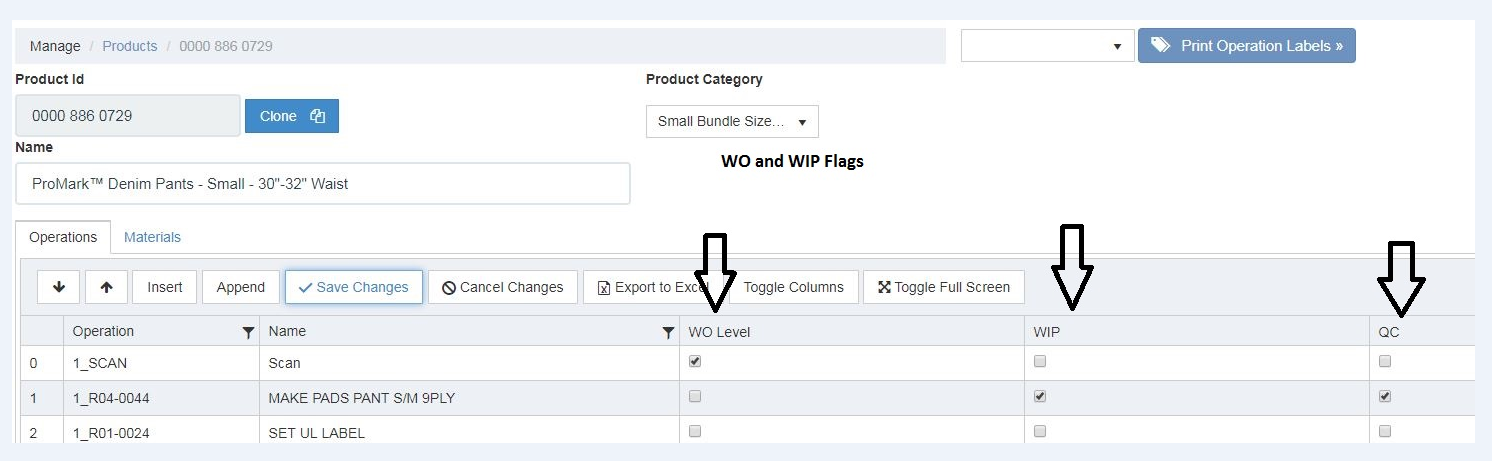

Configure the WO and WIP flags.

WO level means the operation is performed on a workorder level instead of unit level.

In this example, Scan, will mark the entire work order as being in process.

The WIP flag means the operation when scanned will mark the unit as in progress in the WIP tracking.

QC flag means the operation can be controlled for quality using the QC platform.

Copyright © 2020 by Aptean. All rights reserved.

Created with the Personal Edition of HelpNDoc: Maximize Your Productivity with HelpNDoc's Efficient User Interface