LeanLines

Lean Lines

The Lean concept was developed to track a single unit from beginning to end and enabling balancing of users and machines to reduce extra handling.

This means that the SMV is accumulated at the end of the line and divides the SMV amount based on the user time worked on the lean line.

There are different kinds of setups for this depending on the business structure.

Two standard solutions:

- SMV calculated at the end of the line and divided by user time worked on the line

- Grouped BOL SMV with all operations but using the operation sequence and zone concept.

Setup depends on what is traceable; machines, users, etc.

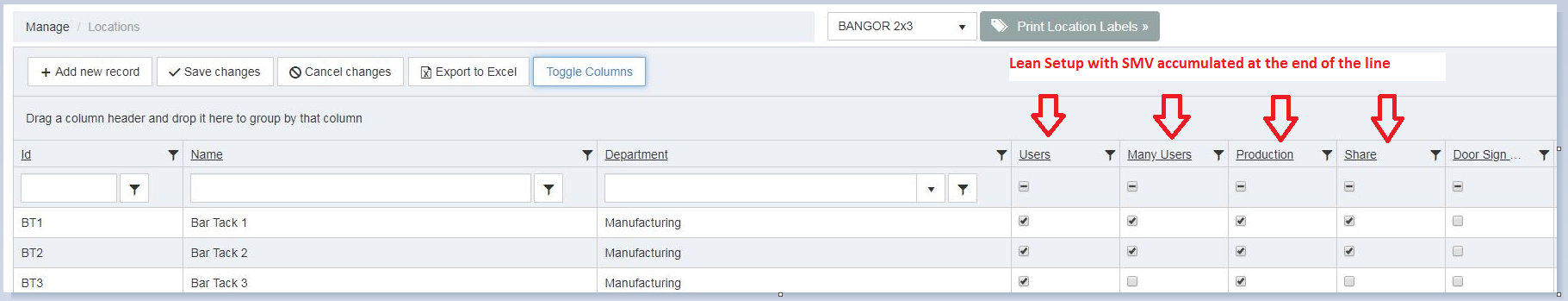

To set up a Lean Line in Shopfloor begin with configuring the locations within the line

Users, Many Users, Production and Share are required.

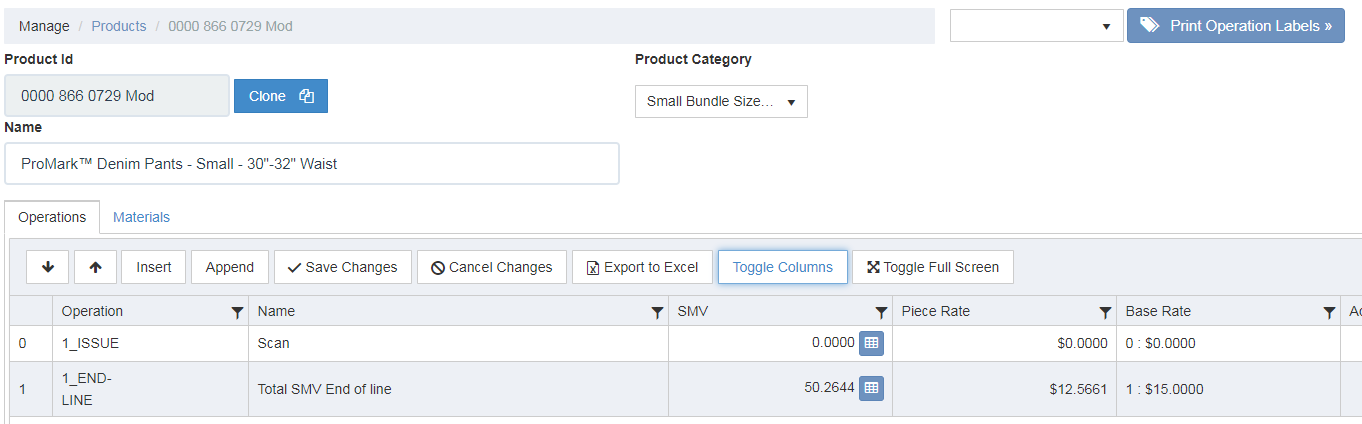

End of the Line SMV

Location setup:

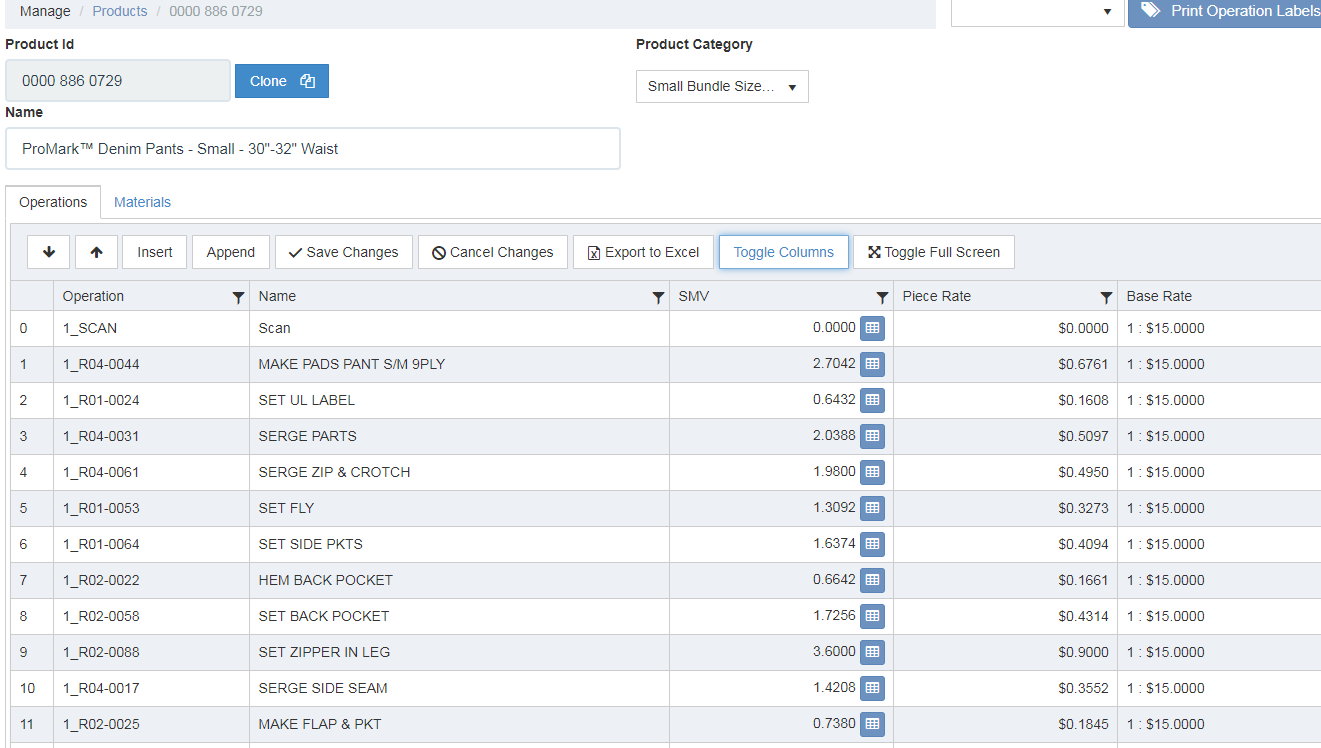

Operations are set up with all operations and their SMVs accumulated into a single operation.

For incentive pay Base Rate is required to calculate the Piece Rate

BOL Setup:

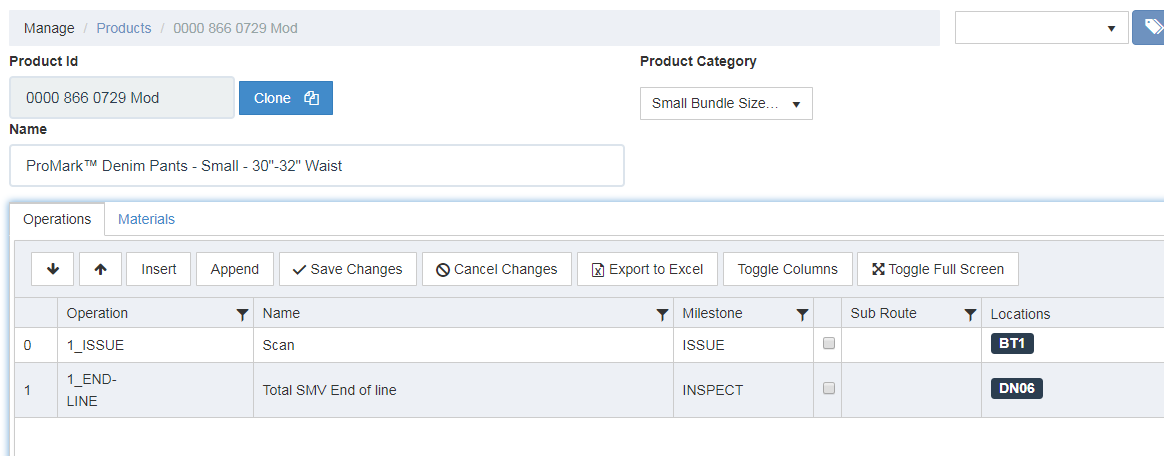

For WIP tracking to function Milestones need to be set up:

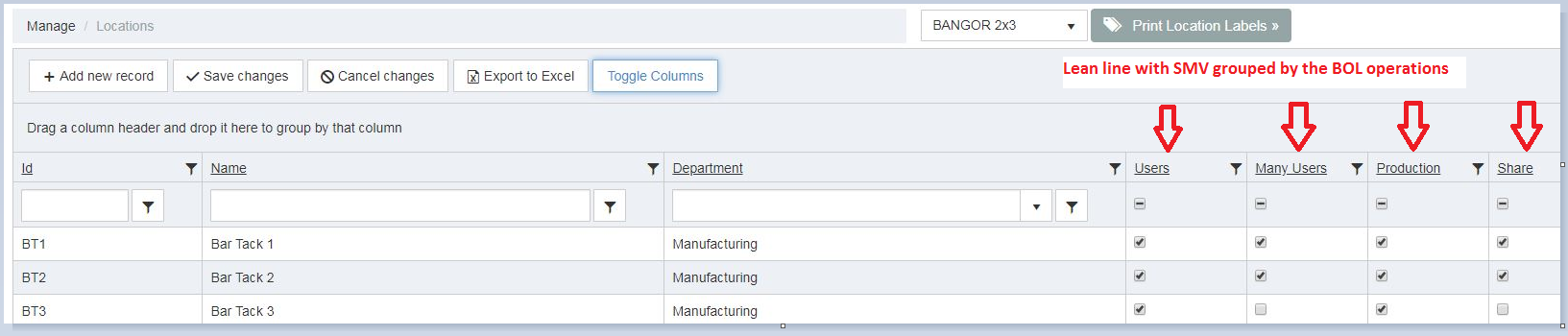

Grouped BOL

Single Location Operation Sequence/Zone: User/Multi Users/Production/Share/Op Seq/Zone è Groups all the SMV of the BOL and marks all the operations as done.

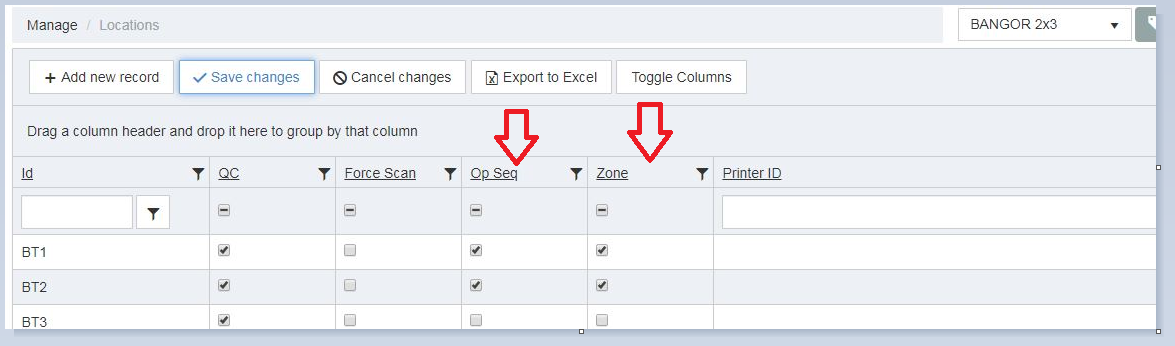

To set this up, the locations in the line need to be set up as follows.

Users, Many Users, Production, Share, (QC), Op Seq, and Zone all need to be checked.

Location Setup:

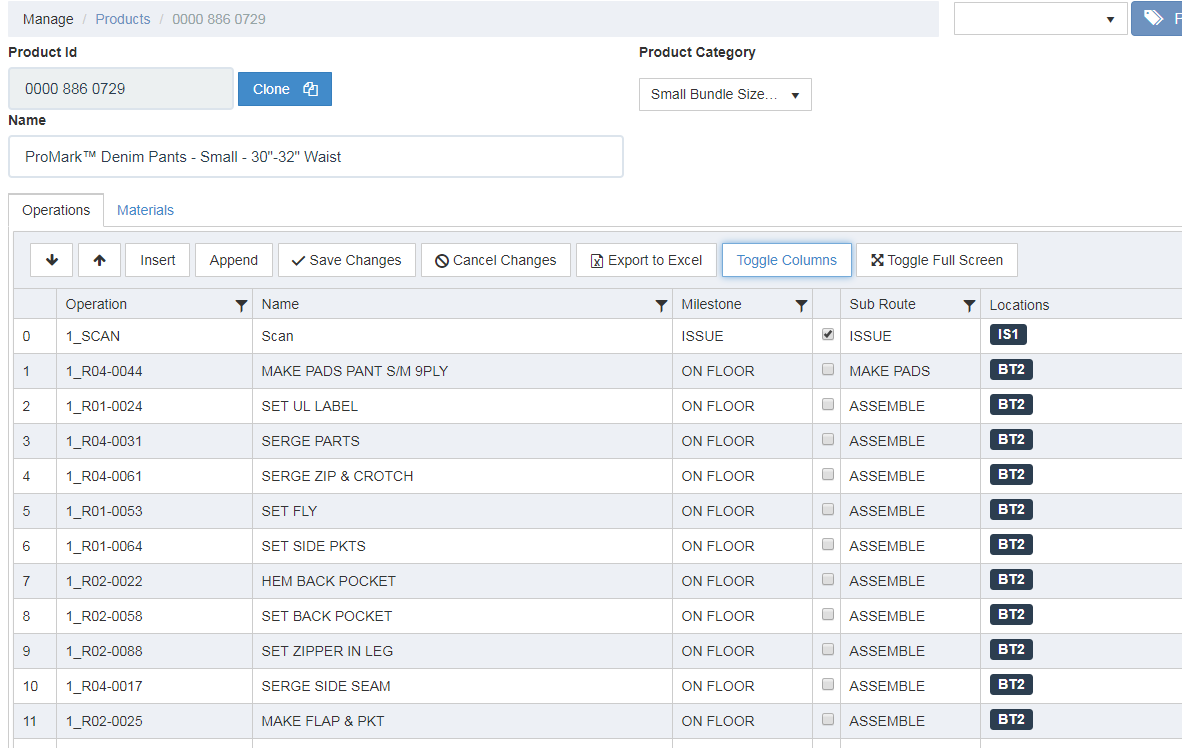

The BOL for the product needs to be set up with individual operations including SMV and the location where the product will be produced.

BOL Setup:

Copyright © 2020 by Aptean. All rights reserved.

Created with the Personal Edition of HelpNDoc: Effortlessly Support Your Windows Applications with HelpNDoc's CHM Generation